Wire-To-Board Connector Solutions in Your Cable Assembly

Cable assemblies comprise of two primary elements - conductor and connector. The sole purpose of a conductor is to pass current at a given voltage, whereas, connectors affix the cable assembly securely to a mating interconnect.

The conductor and connector garner most of the designer’s focus while designing cable assemblies. However, at times the specific details of how to attach the connector to the wire are overlooked.

For instance, forgetting to purchase the appropriate crimp and extraction tooling for your custom cable build will delay your build, especially if these are long lead time or expensive tools. But what happens if three months into your program it’s determined that your specified connector was never meant to attach directly to a cable? What if the wire-to-board connector requires to use as a wire-to-wire connector?

Wire-To-Wire Connector Systems

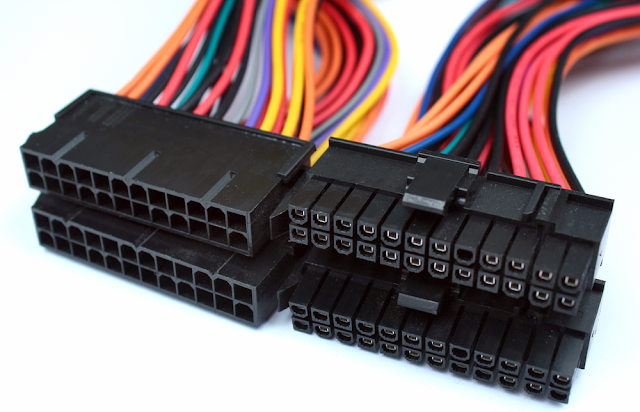

Connectors are designed in wire-to-wire or wire-to-board systems to differentiate the application and installation requirements. These connector systems are self-explanatory and affixed to the male and female sides of the connector using either a soldered or a mechanical connection to a jacketed wire. Your household extension cord is a simple example of a wire-to-wire system.

Wire-To-Board Connector Systems

A wire-to-board connector system consists of a male and female set of connectors, where one terminates to a cable harness and the opposite side attached to a Printed Circuit Board(PCB) Assembly. This type of device connects a wire to PCB, enabling connectivity between circuits.

Instead of using a crimp terminal and housing system, the board side of a wire-to-board connector system uses pins that soldered to through holes or surface mounted to pads on the PCB. This attachment methodology is notably common in surface-mount technology (SMT) manufacturing.

If you find yourself struggling to employ a PCB-mounted connector directly in your cable assembly, there are alternatives to consider, preventing a major design change. However, before exploring some of the possible solutions on how to use a printed circuit board-mounted connector, it is best to analyze the application and use case to completely understand the mechanical, environmental, and electrical requirement impacts.

With over a decades of experience to the printed circuit board Assembly and Manufacturing, PCC develops a varied range of cable & harness products (including Custom Cable Assemblies) that complements with EMS (Electronic Manufacturing Services). We follow strict processes, aimed at zero defects, to ensure manufacturing repeatability and reliability.

Every assembly is customized to precise specifications, ensuring desired lead-time and quality. A right blend of advanced tools and skilled personnel maximize our cable & wire

harness efficiency. Our services are highly cost-effective as compared to other cable harness manufacturers.

Good to see such a nice blog posts Best Contract Manufacturing company in USA

ReplyDelete